Crouvezier Developpement

Since 1860

Séverine Crouvezier

The ennoblement of French textiles

Making a sheet is an incredible adventure. You have to take delivery of the rolls of fabric. Then they have to be cleaned of any roughness with flames, and bleached according to final requirements. Finally, they have to be dried before they can be rolled up.

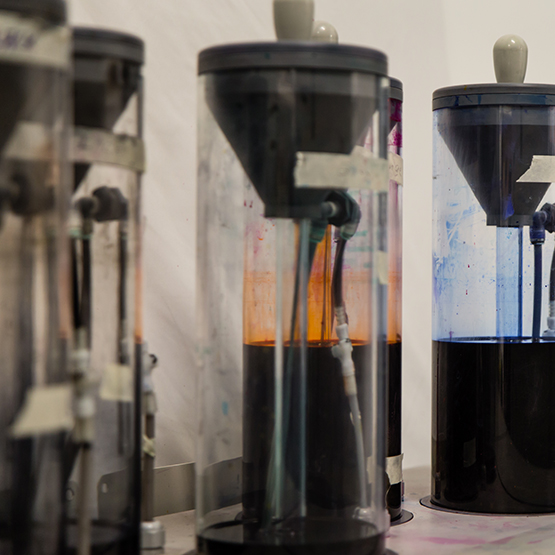

Once in rolls, they are dyed or printed, and then sent to the confectioner. All this requires considerable equipment: some machines alone require an entire warehouse.

From meadow bleaching to highly technical fabrics

Initially, the Crouvezier company only ennobled fabrics by bleaching them "sur prés". Long strips of cloth were washed in river water, mixed with wood ash, and then treated with the acidity of fir trees. Alternating exposure to sunlight and moonlight turned the sheets bright white. The famous "blanc des Vosges". They then adapted their equipment to meet changing needs. As orders increased, they invented a faster drying system, gradually industrializing this ancestral know-how.

Today, the ennobler is the keystone between weaving and finishing. This step transforms a yarn assembly into a fabric that is shrink-proof, wrinkle-proof, stain-proof, mite-proof, flame-retardant, water-repellent, highly visible...

This is where innovation comes into its own, and where the industry stands a chance of remaining in France, developing these high-tech, high-quality fabrics. Whatever the field of application: health, sport, workplace protection, comfort, agriculture, construction, roads, fashion, leather goods, luxury goods... companies in the Vosges have mastered the processes that give fabrics their "superpowers".

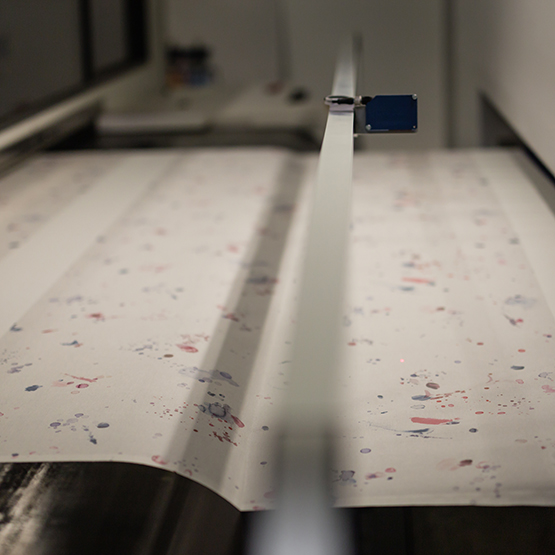

The Crouvezier company has added another string to its bow: printing, a vast playground for innovation and the real highlight of Julie Lavarière's highly qualitative approach.

The future of textiles in the hands of young designers

Séverine Crouvezier has seen the landscape of the Vosges textile industry change over the years. They've had to adapt over time. What hasn't changed since her grandfather's time is the dynamic they've always tried to instill in their company. Always reinvesting to move forward, pointing to innovation and enduring.

The latest addition is a large-format digital printing machine, the only one of its kind in France. With this machine, they are targeting young designers who don't work with quantity, but with high quality. The consumer public is well-informed: they want products that are made in France, ethically and sustainably.

Julie Lavarière is part of this high-end proposition, with products that are entirely designed, woven, printed and made in France. Products that respect health and the environment.

A return to "made in France" that seems to offer a new direction for Vosges textiles.

"New creators are the driving force behind our industry".

In the consumer textile market, as in the food market, people want to be responsible for their purchases, and for things to change. This inevitably involves the consumer: 100% French fabrics are more expensive than others.

"This is due to the human and environmental standards we have to apply, as we have a water treatment plant. We also have to use products authorized in the European Union, such as nanoparticle filters," explains Séverine Crouvezier.

In short, these are high-quality, eco-responsible products.