Flashback: only 15 years ago, textile printing was carried out solely using engraved cylinders installed on rotary presses. Today, printing is digital, an evolution that opens up many new perspectives!

A cylinder 64 centimeters in diameter and 3 meters long, one for each color, installed side by side, and the fabric passing through, printed color by color until the complete pattern is obtained. This technique inevitably requires large quantities: one cylinder alone costs 700 euros to create. For ten colors, the cost of textile printing already reaches 7,000 euros without a single meter of fabric being printed!

Digital printing: the revival of textile printing

Towards the end of the 90s, printing requirements and cost-cutting were no longer compatible, and textile printers could only watch customers flee to Asia and Pakistan. Digital printing is bringing some orders back to France, particularly for luxury bed linen. Julie Lavarière is a fine symbol of this French commitment, breathing new life into these textile printing craftsmen with their unique know-how.

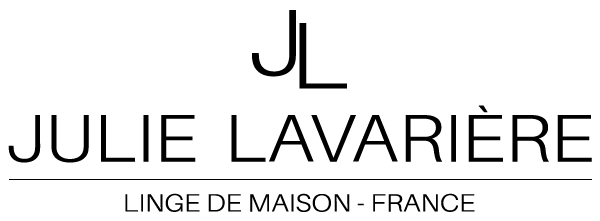

Digital printing also offers a quality that cannot be achieved with rotary printing. Traditional techniques allow a maximum of twelve colors, following a simple design, with colors clearly separated from each other and without gradations. The shape of the print itself has its constraints: the rollers are 64 cm in diameter. This means that the same motif is mechanically repeated every 64 centimetres. Digital printing opens up a whole new world of possibilities in terms of orders, enabling brands to create capsule collections for an extremely specialized and rare offer. But also in terms of prints. Today, it's possible to print a unique design rather than just a motif.

High-quality textile prints

Quality is now the order of the day. Graphic quality first and foremost: as we've seen, the ability to print unique designs means you can create rare sets of beds, veritable works of art. Print quality also serves a simple motif, through the rendering of gradations. It is no longer necessary for the colors to be separated from each other to be applied to the fabric by the various rollers. It is therefore possible to render even subtle color gradations in print. All the strength of a line, the luminosity of a hue, the subtlety of a nuance will find its translation on the fabric.

Quality, too, because colors hold better, thanks to the very process of applying them to the fabric, which means they can be washed at up to 60° with no loss of color vibrancy.

A field of possibilities that today enables Julie Lavarière to offer unique, 100% French quality bed linen with an exceptional graphic proposition. The works of the textile artists featured on Julie Lavarière bed linen sets come to life, revealing all the richness of their strokes, the depth of their gradations, the strength of their lines, thanks to this unique digital printing process.